Manufacture

Paramount machinery to provide the high quality products promptly and continuously

The advanced manufacturing technology needs special equipment in order to achieve excellent results.

Yashiro factories are fully equipped with state‐of‐the‐art machines, especially a maximum load 3,000 ton press machine.

Such kind of new machine improve the Yashiro's manufacturing capabilities in combination with the original methods that we have been cultivating for more than a half century.

In addition, we have shown high quality craftsmanship in small quantity products, such as front masks for rolling stocks.

Our singular hand lay-up method enables us to reconcile toughness, high capacity and elegant appearance in these products.

We have also developed mid-temperature molding (called electroforming) technique which tremendously increased productivity for mass production of cultured marble bath tubs.

DCPD (Dicyclopentadiene) and RIM(Reaction Injection Molding) method permits us to produce heavy, complicated medical equipment components in an extremely short time.

By the autoclave method using carbon prepreg, we produce automobile components (such as diffusers), rolling stock components (such as front coupler covers for the Shinkansen), and aircraft components.

TMC produced in our in‐house plant are speedily manufactured into well-formed, high quality products through the pressing processes of our integrated production system.

It is an age when not only the quality but also the difference of a slight nuance on the design are demanded for an individual product recently.

Now our experience which we had developed FRP for long period has been freely demonstrated in the detail of our products.

So it can be said that our age has come.

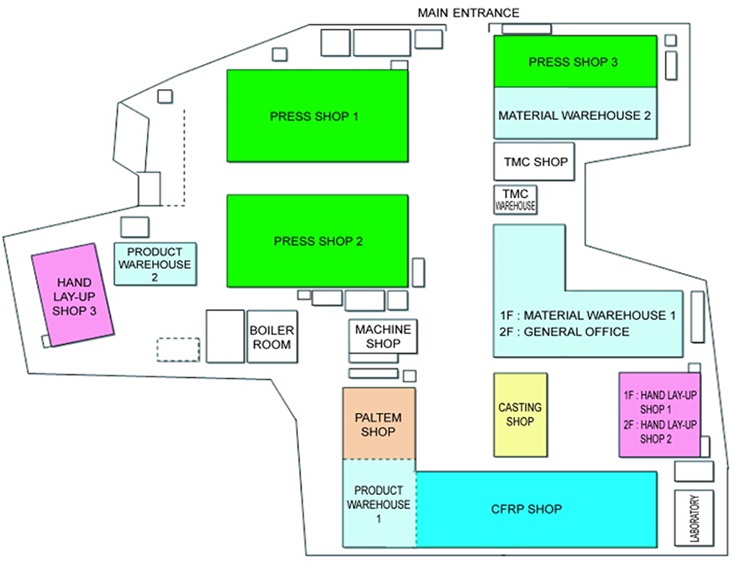

FACTORY